July 31: In the world of modern manufacturing, precision engineering plays a critical role in ensuring accuracy, safety, and consistent performance. At the forefront of this domain, GodrejEnterprisesoffers bespoke engineering services that address complex challenges across industries. Whether it’s India’s nuclear power sector or advanced aerospace applications, their custom-engineered systems deliver unmatched results. With decades of experience, state-of-the-art facilities, and certified processes, they are a trusted partner in high-stakes, mission-critical projects, where precision isn't an option, but the standard.

Why Precision Engineering Is Essential

Precision engineering is the backbone of critical industrial systems. It is the art and science of designing components that must function flawlessly under exact conditions. Generic solutions often fail in high-pressure or regulated industries, where accuracy and durability are vital.

Key Advantages:

- High tolerance levels

- Better performance under stress

- Long-term reliability

- Reduced downtime and error rates

Godrej’s custom systems are tailored for operations where no margin for error is acceptable. From temperature-sensitive environments to high-speed production lines, precision ensures efficiency and safety.

Customisation for Industry-Specific Demands

Each industry operates in a unique environment. This requires highly customised engineering approaches. Godrej Enterprises Group addresses these challenges with in-depth consultations and technical design capabilities.

Sectors Served:

- Nuclear Energy: First-ever ‘Made in India’ nuclear projects

- Automotive and Aerospace: Extreme accuracy in vibration control

- Transportation: Shock absorbers designed for load-bearing endurance

Their design and product development teams work closely with clients to understand system goals, boundary conditions, and regulatory needs. No two solutions are the same, because no two challenges are.

Core Capabilities That Drive Performance

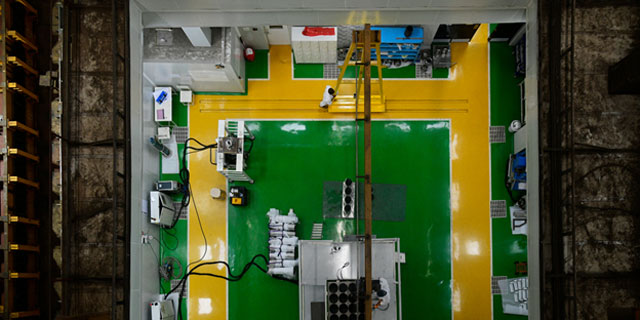

Godrej’s precision engineering expertise is supported by several in-house capabilities that allow full control over every project.

Key Areas of Expertise:

- Design & Product Development: Custom systems designed from the ground up

- Assembly: Error-free integration of electrical and mechanical components

- Fabrication & Machining: Use of advanced tools and CNC systems

- Electrical & Electronic Systems: Integrated solutions for digital and automated machinery

- Metallurgical Testing: NABL-accredited lab ensures quality of materials

All components are tested for durability, fatigue, and performance. Their metallurgical testing lab verifies that each material used can endure demanding environments.

Long-Term Partnership with the Nuclear Sector

For over 20 years, Godrej Enterprises Group has worked closely with the Nuclear Power Corporation of India. This long-standing partnership is a testament to their commitment to quality, trust, and technological advancement. They have contributed to:

- Equipment for power generation

- Assemblies for mission-critical nuclear applications

- Safety-tested mechanical components

Their solutions follow rigorous standards and are often tested under conditions harsher than operational requirements. This ensures safety, precision, and compliance at every level.

Certified for Excellence and Reliability

Godrej holds international certifications that prove their dedication to process quality, environmental responsibility, and workplace safety. Their certifications include:

- ISO 9001:2015 - Quality Management Systems

- ISO 14001:2015 - Environmental Management

- ISO 45001:2015 - Occupational Health & Safety

- NABL:2015 - Accredited Metallurgical Testing Lab

These certifications aren’t just labels; they reflect a commitment to structured, repeatable, and safe engineering processes. It also builds confidence in clients from regulated industries.

Sustainable and Responsible Engineering

Sustainability is a key focus for Godrej Enterprises Group. Their precision engineering processes are designed to reduce environmental impact, conserve energy, and optimise resources. They achieve this by:

- Using recyclable materials in manufacturing

- Low-emission processes in fabrication

- Extended life cycles to reduce equipment waste

- Lean manufacturing to cut down material waste

Custom-engineered solutions are also designed with life cycle efficiency in mind. This approach results in less frequent replacements and repairs, making the solutions more sustainable over time.

Technology-Driven Innovation

Precision engineering at Godrej is powered by technology. Their teams regularly integrate next-generation tools and smart solutions into custom systems like:

- 3D CAD tools for accurate product visualisation

- IoT-enabled systems for real-time monitoring

- Smart shock absorbers and adaptive suspension systems

- CNC-based machining for ultra-fine tolerance levels

Such innovations enable clients to track performance, predict faults, and reduce maintenance downtime, all contributing to lower cost of ownership and better ROI.

Enhanced Operator Safety and System Integration

Safety is not just about equipment. It includes the people who use it. Godrej incorporates safety-first features into its customised engineering designs, like:

- Ergonomic controls for operator comfort

- Fail-safe systems that prevent overload

- Intelligent monitoring tools to avoid system failure

- Sealed systems to prevent contamination in sensitive sectors

Whether it’s a heavy-duty machine or a high-precision testing system, each solution is built with both operator and system protection in mind.

Precision Engineering for Global Standards

In today’s global marketplace, products must meet not just national but international standards. Godrejoffers precision engineering solutions that enable clients to enter new markets with ease, including:

- Products that meet ISO and ASME standards

- Design adaptability for varying regional regulations

- Support with documentation and compliance verification

This global approach reduces entry barriers, avoids costly penalties, and improves product credibility across different geographies.

Conclusion

Godrej Enterprises Group leads the way in precision engineering with its customised solutions for complex and high-stakes industries. Their deep understanding of industry-specific challenges, along with unmatched technical capabilities, enables them to deliver tailored systems that improve performance, safety, and compliance.

From nuclear energy to heavy industrial equipment, their work proves that precision is not just about accuracy; it’s about enabling long-term success. As industries continue to evolve, partnering with Godrej ensures you stay ahead with reliable, innovative, and expertly crafted engineering solutions. When the challenge is tough, precision is everything, and Godrej delivers it every time.